The Fats, Oils, and Grease Program outlines the wastewater pretreatment requirements for Food Service Establishments (FSE) and other commercial facilities that discharge fats, oils and grease in their wastewater flow. All new and existing Class III and IV and Food and Drug Administration (FDA) Class 2, 3 and 4 FSEs or any other facility that discharge fats, oils and grease in their wastewater must comply with the Connecticut Department of Energy and Environmental Protection’s General Permit for the Discharge of Wastewater Associated with Food Service Establishments issued on October 5, 2015.

Upon installation of the required properly sized Super Capacity Grease Interceptor (SCGI) or outdoor in-ground minimum 1,000 gallon interceptor the FSE must complete a Facility Registration form and schedule an inspection with MDC to receive approval.

For questions or to schedule an inspection please contact Magen Bakaj at (860) 278-7850 ext 3239 or by email at FOG@themdc.com.

Downloadable Forms

General Permit for the Discharge of Wastewater Associated with Food Service Establishments

Facility Registration Form

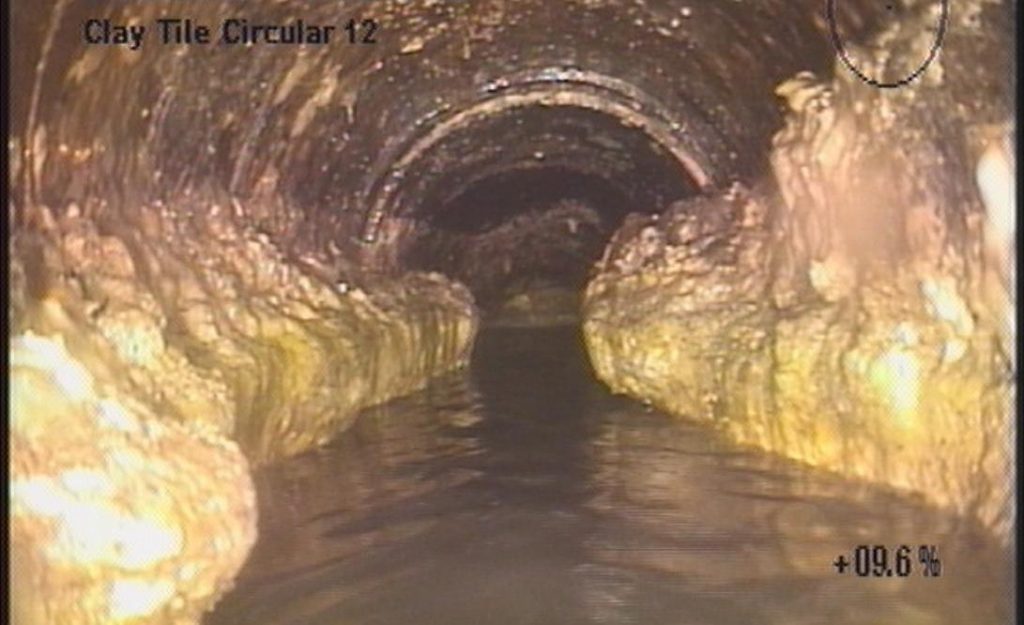

Impacts of Fats, Oils and Grease buildup on an MDC sewer

FINES AND FEES

Annual Fee

An annual fee of $150.00 will be billed to each of the Class III and IV and FDA class 2, 3, and 4 Food Service Establishments (FSEs) in the Metropolitan District. This fee is associated with the review and approval of facility registration forms as well as inspections. For 2023, the Annual Fee invoice will be invoiced monthly at the rate of $12.50 per month.

FSE registration or variance approvals will expire three years after the issuance date. The FPE shall submit a Registration or Variance Application form 30-days prior to the expiration of the FPE’s current registration.

Inspections Violation Fees

The MDC will perform inspections of the FSEs to determine compliance with the Department of Energy and Environmental Protection’s (DEEP) General Permit for the Discharge of Wastewater Associated With Food Service Establishments. Each day that a violation continues shall be a separate occurrence of the violation according to section S15 of the MDC Sewer Ordinances.

The Inspection Violation Fees are as follows:

| Failure to Submit Registration or Variance Applications | $500 |

| Disallow Inspection | $225 |

| No FOG management equipment installed | $200 |

| Non-compliant FOG management equipment installed | $200 |

| Failure to maintain grease trap cleaning, inspection and maintenance records in proper order | $100 |

| Failure to maintain FOG management equipment in proper working order | $200 |

| Failure to clean FOG management equipment quarterly or when 25% of the depth of the trap is filled with food solids and FOG, whichever comes first | $200 |

| Failure to properly dispose of brown and/or yellow grease | $200 |

| Source of sewer blockage | $1000 |

| Source of sanitary sewer overflow (minimum) – Actual costs will be billed to the facility for the time and materials related to the overflow | $1000 |

The payment of the fee will be required 30 days following issuance of the notice of violation invoice.

Violation Correction Schedule

| Equipment not registered | 7 days |

| No grease trap installed or non-compliant grease trap installed | 30 days |

| FOG management equipment in need of repair or cleaning | 7 days |

Failure to maintain written records of FOG management

equipment cleaning and inspection | 7 days |

Disallow an inspection – Inspection must be scheduled within

7 days of initial inspection | 7 days |

Failure to clean and maintain FOG management equipment

as required | 7 days |

| Source of sewer blockage | 24 hours |

| Source of sanitary sewer overflow | 24 hours |

$75 fee for not complying with the NOV within the schedule listed above

Emergency Call Out Fees

The MDC will perform emergency call outs to relieve grease blockages that result in sewer backups. If MDC determines that the grease problems in the sewer infrastructure were a result of the FPE, the establishment will be billed for the work performed by the MDC to relieve the blockage. The payment of the fee will be due within 30 days of the issuance of the invoice.

GREASE TRAP OPTIONS

All Class III and Class IV and FDA class 2, 3, and 4 Food Service Establishments (FSEs) are required to install either an Active Grease Recovery Unit (AGRU), Super Capacity Grease Interceptor (SCGI), or a minimum 1,000 gallon outdoor in-ground passive grease interceptor. Specific requirements for these devices are outlined in the General Permit. All of the following fixtures must be connected to FOG Management Equipment:

- pot sinks (3 bay sinks)

- pre-rinse sinks;

- any sink into which fats, oil, and grease are likely to be introduced;

- soup kettles or similar devices; wok stations;

- floor drains or sinks into which kettles may be drained;

- automatic hood wash units; and

- any other fixtures or drains that are likely to allow fats, oils and grease to be discharged.

Active Grease Recovery Unit (AGRU)

Active Grease Recovery Units (AGRUs) are relatively small pretreatment units that can be located inside a kitchen to remove grease at the source of generation. These units allow fats, oils, and grease (FOG) to accumulate within the unit while skimmers or pumps remove the FOG from the unit and deposit the material in a separate container for disposal by a grease removal contractor.

All AGRUs shall be maintained in accordance with the manufacturer’s recommendations. This includes a minimum quarterly (four times per year) clean out of the entire unit. The contents of the trap must be placed into a container for grease trap waste (brown grease). A written log and receipts of all cleaning and maintenance of the trap must be maintained on site for review by the MDC.

See links below for the:

Sample AGRU Maintenance Log

AGRU Best Management Practice Poster

List of AGRU vendors, Grease Trap Cleaners and Grease Removal Contractors (2019)

Super Capacity Grease Interceptor (SCGI)

Approved Super Capacity Grease Interceptors (SCGIs) are defined as indoor passive units that are certified to retain more than four times the weight (lbs) of grease than the flow rating in gallons per minute (GPM) and meet specifications defined by Section 5(b)(3) of the General Permit.

All SCGIs shall be maintained in accordance with the manufacturer’s recommendations. This includes a minimum quarterly (four times per year) clean out of the entire unit. The contents of the trap must be placed into a container for grease trap waste (brown grease). A written log and receipts of all cleaning and maintenance of the trap must be maintained on site for review by the MDC.

OUTDOOR IN-GROUND GREASE TRAP/INTERCEPTOR

An outdoor in-ground grease trap must be emptied at least every three months or whenever 25% of the operating depth of the grease trap/interceptor is occupied by grease and settled solids, which ever is more frequent. Following a minimum one year of operation, the facility may submit a request to the MDC to extend the cleaning beyond the three month period if the facility demonstrates that the level of grease and solids was less than 25% during each of the three month intervals. The facility shall maintain a written log and receipts of all cleaning and maintenance of the trap.

Please see links below for the:

Cleaning Log for Outdoor Grease Interceptors

Outdoor Grease Interceptor FOG Maintenance Requirements Poster

The Standard Specification for MDC outside grease interceptors for kitchens is shown below:

The outdoor grease trap/interceptor specifications are described in Section 5(b)(1) of the General Permit. Installation of a new outdoor grease trap/interceptor shall meet the specifications as described in the General Permit and the MDC specifications.

COMPLIANCE DATES

Food service establishments and facilities that are applicable to this General Permit shall comply based on the following schedule:

All new facilities shall comply with the requirements of the General Permit before initiating such discharge. An existing facility, which begin operation prior to the effective date of the General Permit (September 30, 2005), shall comply with the requirements of the General Permit no later than July 1, 2011.

BEST MANAGEMENT PRACTICES

- Renderable fats, oils, and grease shall be disposed of in separate storage containers for recycling by a renderer. No renderable fats, oils, and grease shall be discharged into grease trap/interceptors or AGRUs, sanitary sewers, dumpsters or storm sewers.“Renderable” means uncontaminated fats, oils and grease from the food preparation process that can be used as a source of material that is free of impurities and can be recycled into products such as animal feed and cosmetics.

- The owner/operator shall perform at least quarterly inspections of all indoor and outdoor grease trap/interceptors.

- For disposal in Connecticut, the contents of all grease trap/interceptors, AGRUs and other approved units shall be disposed of at a regional collection/transfer/disposal site. For disposal outside of Connecticut, the contents of all grease trap/interceptors, AGRUs and other approved units shall be disposed of in an environmentally accepted manner.

- The permittee may use hot water, steam, chemicals, or biological additives in the normal course of facility maintenance, but may not intentionally use hot water, steam, physical means, chemicals, or biological additives that will cause the release of fats, oils, and grease from the grease trap/interceptor. (Please see the link below for additional information.)

- No food grinder (garbage disposal) or food pulper shall discharge to any grease trap/interceptors, AGRUs or other approved units.

- All wastewater flows connected to the grease trap/interceptors shall be screened to prevent solids from entering the treatment units. Screened solids shall be disposed of in accordance with applicable solid waste regulations.

For additional information and guidance please go to the following link:

Best Management Practices and Guidance Manual for Food Preparation Establishments (2019)

VARIANCE PROGRAM

The Metropolitan District (MDC) may grant a variance of treatment requirements for a FPE for a period of three years. This variance is a waiver of the treatment requirements of Sections 5(b)(1) through 5(b)3, inclusive, of the Department of Energy and Environmental Protection’s (DEEP) General Permit for the Discharge of Wastewater Associated With Food Preparation Establishments. The applicant must demonstrate there is a limited potential for fats, oils, and grease in the discharge, as well as minimal flow. If the MDC encounters any grease problems in the sewer infrastructure in the area of the establishment, MDC has the right to revoke any variances issued.

Please note the applicant must reapply for a variance approval 30-days prior to the following:

- expiration date of the three year approval period or;

- any significant menu or operational changes that would increase the potential for fats, oils, and grease in the discharge or;

- change of ownership.

To be considered for a variance, the facility shall complete the Variance Application and attach a complete menu for the establishment. The application shall include a description of the proposed methods for minimizing grease discharged in the wastewater, including employee training, cleaning procedures and interim grease disposal methods.

Variance Application 2020